1. Classification by rolling bearing structure type

(1) According to the load direction or the nominal contact angle that the bearing can bear, it can be divided into:

1) Radial bearing is mainly used to bear radial load of rolling bearing, its nominal contact angle from 0 to 45.

According to the different nominal contact angle, it can be divided into three parts

Radial contact bearing: radial bearing with nominal contact angle of 0

Radial angular contact bearing ---- radial bearing with nominal contact angle greater than 0 to 45.

2) Thrust bearing is mainly used to bear axial load of rolling bearing, its nominal contact angle is greater than 45 to 90.

According to the nominal contact angle, it can be divided into three parts

Axial contact bearing: thrust bearing with nominal contact angle of 90

Thrust angular contact bearing ---- thrust bearing with nominal contact angle greater than 45 but less than 90.

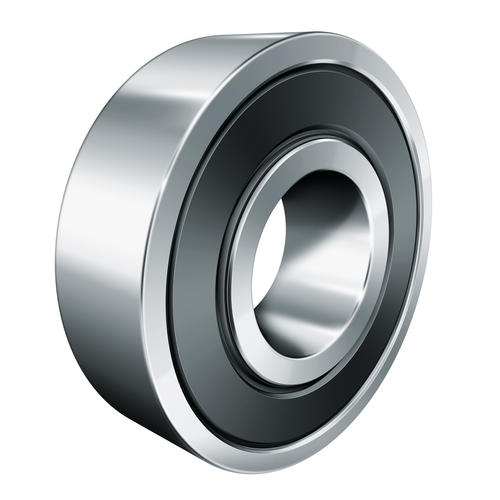

(2) According to the types of rolling elements, bearings are divided into:

1) Ball bearing: the rolling element is ball

2) Roller bearing - the rolling element is roller. According to the types of rollers, roller bearings are further divided into:

Cylindrical roller bearing - rolling element is cylindrical roller bearing, the ratio of length and diameter of cylindrical roller is less than or equal to 3;

Needle roller bearing ---- the rolling element is the bearing of needle roller. The ratio of needle length to diameter is greater than 3, but the diameter is less than or equal to 5mm;

Tapered roller bearing - rolling element is tapered roller bearing;

Self aligning roller bearing - rolling element is spherical roller bearing.

(3) According to whether the bearing can be self-aligning during operation, it is divided into three parts

1) Self aligning bearing ----- the raceway is spherical, which can adapt to the angular deviation and angular motion between the axis lines of two raceways;

2) Non self aligning bearing (rigid bearing) - bearing that can resist the angular deviation of the axis line between raceways.

(4) According to the number of rolling element columns, bearings are divided into:

1) Single row bearing - bearing with a row of rolling elements;

2) Double row bearing - bearing with two rows of rolling elements;

3) Multi row bearings ---- bearings with more than two rows of rolling elements, such as three row and four row bearings.

(5) According to whether the parts of bearings can be separated, they are divided into three parts

1) Separable bearing - bearing with separable parts;

2) Non separable bearing - bearing in the final matching, rings are not free to separate the bearing.

(6) According to its structural shape (such as whether there is a filling groove, whether there is an inner ring, an outer ring, the shape of the ring, the structure of the rib, and even whether there is a cage, etc.), the bearing can also be divided into a variety of structural types.

2. According to the size of rolling bearing, the bearing is divided into three parts according to its outer diameter

(1) Miniature bearing ---- bearing with nominal outer diameter less than 26mm;

(2) Small bearing - bearing with nominal outer diameter of 28-55mm;

(3) Small and medium sized bearings - bearing with nominal outer diameter of 60-115mm;

(4) Medium and large sized bearing - bearing with nominal outer diameter of 120-190mm;

(5) Large bearing - bearing with nominal outer diameter of 200-430mm;

(6) Oversize bearing - bearing with nominal outer diameter over 440mm.

There are many types and sizes of rolling bearings. In order to facilitate the design and selection, the standard stipulates that the type, size, structural characteristics and tolerance grade of rolling bearings are represented by codes.

National standard: GB / t272-93 (to ISO) (instead of gb272-88), the composition of rolling bearing code is shown in the attached table. Code representation method of rolling bearing code purpose: to characterize the structure, size, type, accuracy, etc. of rolling bearing. The code is specified by the national standard GB / t272-93. Code composition:

Front code - the component of bearing;

Basic code - indicating the main characteristics of bearing such as type and size;

Post code - indicates the accuracy of the bearing and the characteristics of the material.

Inner diameter Code: inner diameter code × 5 = inner diameter special case: D = 10 12 15 17 Code: 00 01 02 03 size series code: used to express bearings with the same inner diameter but different outer diameter and width, see the right figure. Outer diameter series code: extra light (0,1), light (2), medium (3), heavy (4) width series code: general normal width is "0", usually not marked. But "0" cannot be omitted for tapered roller bearings (Class 3) and self-aligning roller bearings (Class 2)

suffix definition

C3: radial clearance is larger than ordinary clearance

K: 1 / 12 taper taper hole

K30: 1 / 30 tapered hole

M: Machined brass solid cage guided by steel ball

2RS: with sealing cover at both ends

TV: glass fiber reinforced polyamide solid cage guided by steel ball

For the bearing configuration with heavy load, bad working conditions or special sealing requirements, the built-in contact type self-aligning roller bearing can be used. The dimension of the bearing is the same as that of the unsealed bearing, so it can replace the unsealed bearing in many occasions. The allowable alignment angle is 0.5 ° and the working temperature [2] is - 20 ℃ ~ 110 ℃. The bearing has been filled with an appropriate amount of lithium base anti rust grease, or the grease can be added according to the user's requirements. According to whether the inner ring has rib or not and the cage used, it can be divided into two basic types: C-type bearing and Ca type bearing. The characteristic of C-type bearing is that the inner ring has no rib and the cage is pressed by steel plate. The characteristic of Ca type bearing is that both sides of the inner ring have rib and the cage is made by car. This kind of bearing is especially suitable for working under heavy load or vibration load. The self-aligning roller bearing is equipped with drum roller bearing between the inner ring with two raceways and the outer ring with spherical raceway.

Ask a quote for the latest price and one of our team members will respond as soon as possible. Fields marked with * are required.